Sewage Treatment Plants

A sewage treatment plant is the modern way to treat wastewater and sewage. These plants produce a liquid that is non-polluting and produces clear-water. This water can then be discharged directly in to a ditch, strem or a river and has the benefit that it does not cause harm to fish or other wildlife. This is achieved by utilising millions of friendly aerobic (oxygen breathing) bacteria which digest the organic pollutants in the sewage and wastewater.

6 Important Things To Consider -

TANK WARRANTY PERIOD

A minimum 5 Year Free Warranty is essential. Some only have 12 months which is not enough to protect you as tanks rarely fail in the first 12 months.

INTERNAL MOVING PARTS

Sewage is corrosive, so a sewage plant with no internal moving parts or metal components has an advatage.

ELECTRICITY CONSUMPTION

The most efficient 6 person sewage plant uses only 34 Watts/ Hour. Whilst the least efficient treatment plants can use up up to 135 Watts/ Hour.

BLOWER POSITIONING

The plant's blower should be positioned outside the tank, never inside it. Inside the tank, the humidity is 100%. Water and electricity are NOT a good combination.

SERVICE AND EMPTYING

These can vary quarterly to annually. A plant which needs an annual service will save you around £130/ service and £150/ emptying.

ONE PIECE CONSTRUCTION

It is best to avoid tanks constructed of two pieces or more. Even the best seals will eventually fail and the plant could then be in serious trouble. As could your land be with the Environment Agency.

TYPES OF SEWAGE TREATMENT PLANTS

Activated Sludge Plants

- Vortex

- WPL Diamond

- Conder ASP

- Bio Pure

- Bio Digester

Submerged Aerated Filters

- Falcon

- Valance

- Tricel

- Envirosafe

Biodiscs

- Klargester Biodisc

Filter Systems

- Conder Eco

- Bio Rock

- Filterpod

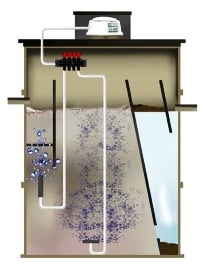

Activated Sludge Plants

This type of plant has replaced many submerged aerated filter models.

Activated Sludge Technology use two stages of dealing with commerical and residential sewage / waste water:

- They have no primary settlement tanks.

- Secondary Treatment The sewage flows straight to the digestion chamber or 'Biozone', where the organic material in the sewage is digested. The Activated Sludge process is a natural biological treatment process, involving many different sorts of bugs. In the Activated Sludge Plant (ASP) bacteria produce sticky substances that coat the bits of organic material in the sewage. The particles stick together to form lumps or 'flocs', creating a structure within which the bugs live. The milk chocolate coloured activated sludge is aerated to dissolve oxygen in the sewage liqor, which allows the bacteria to breathe and the organic matter (BOD) to be digested by the bugs.

- Final Settlement / Clarification The sewage effluent then flows to a clarification chamber, where the flocs sink to the bottom and are transferred back to the digestion chamber.

The tank should be big enough to allow sufficient contact time (retention time) between the sewage and the activated sludge for all the digestion to take place.

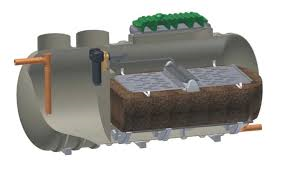

Submergerged Aerated Filters

These plants became popular in the 1990's.

Submerged Aerated Filter technology uses three stages of dealing with commerical and residential sewage / waste water:

- Primary Settlement Larger solids settle into the bottom of the primary tank and buoyant material float to the top to form a crust. These are both removed periodically by tanker.

- Secondary Treatment Suspended solids, floating in the liquor, transfer to the Biozone for digestion by the bugs. The air required by the bugs to breathe is supplied by a blower that bubbles air through the chamber. The chamber is also filled with media - usually plastic shapes with a lot of surface area for the bugs to grow on and attach to.

- Final Settlement / Clarification Where remaining solids and dead bacteria (Humus) are settled out of the biological treated effluent.

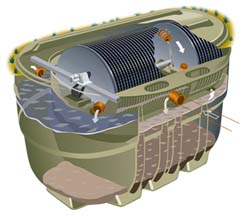

Biodiscs

These are the original sewage treatment plant designed in the 1970's.

Biodisc technology uses three stages of dealing with commerical and residential sewage / waste water:

- Primary Settlement Larger solids settle into the bottom of the primary tank and buoyant material float to the top to form a crust. These are both removed periodically by tanker.

- Secondary Treatment Suspended solids, floating in the liquor, transfer to the Biozone for digestion by the bugs. The biozone has within it a compact series of rotating discs, driven by an internal motor and gearbox, which continually turns the discs. The bugs grow on the discs and breathe as the discs turn out of the sewage and into the air, so the sequence is 'Breathe, Eat, Breathe, Eat'.

- Final Settlement / Clarification Where remaining solids and dead bacteria (Humus) are settled out of the biological treated effluent.

Filter Systems

These are the original sewage treatment plant designed in the 1970's.

Biodisc technology uses three stages of dealing with commerical and residential sewage / waste water:

- Primary Settlement Larger solids settle into the bottom of the primary tank and buoyant material float to the top to form a crust. These are both removed periodically by tanker.

- Secondary Treatment Suspended solids, floating in the liquor, transfer to the Biozone for digestion by the bugs. The biozone has within it a compact series of rotating discs, driven by an internal motor and gearbox, which continually turns the discs. The bugs grow on the discs and breathe as the discs turn out of the sewage and into the air, so the sequence is 'Breathe, Eat, Breathe, Eat'.

- Final Settlement / Clarification Where remaining solids and dead bacteria (Humus) are settled out of the biological treated effluent