SEPTIC TANKS

Septic tanks are made from a variety of materials.

- Brick/concrete - Usually older tanks and of the 2 chamber design

- Fibreglass

- Plastic

It is vital to check that the tank does not leak, is not cracked or split and that the seals are intact. If not, then sewage can leak out in dry periods, contaminating public drinking water supplies. Groundwater can also leak during wet weather, flooding the soakaway. Many old brick and concrete tanks become porous with age and if over 30 years old, should be inspected very carefully when emptied.

Many newer fibreglass septic tanks only ever have a 12 month tank warranty. These should be inspected every year for cracks and the baffle should be tested to make sure that it is still attached to the wall of the tank.

SEPTIC TANK TYPES

'Onion' Bulb Tanks

These are the most common types of septic tanks on the market and are the cheapest to buy.

A 'sphere' shape has the highest volume / surface area, so less fibreglass or plastic is used in the construction. This does not mean that it is the best design - just the cheapest.

They were virtually the only septic tanks made from 1975 until the year 2000, until some manufacturers reverted to the tried and tested traditional two chamber design, even though it was more expensive to manufacture.

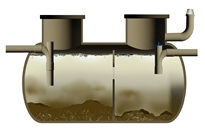

Two Chamber Tanks

These are now making a comeback. The design of the tank gives much more distance between inlet and outlet pipe for settlement of the solids. They are based on the traditional brick /concrete design that was built from the 1900's and which is the type that features in the BS 6297 for recommended 'Small scale sewage treatment system design'.

They are low profile, easier to install and give a lower level of pollutants in the septic effluent.